Recyclable Flat Bottom Pouches

PCR PE Pouches( High barrier with Recycled PE)

MDO-PE / PE( High barrier 100% recyclable Mono Material)

PE / EVOH PE(High Barrier 100% Recyclable Mono Material)

Why Recyclable Flat Bottom Pouches?

- 100% fully recyclable Mono-material PE flat bottom pouches

- High Barrier, better protect the products

- Transparent, can see the packed products

- Custom print available

- Aluminium-free, no foil, no metalized, no PET

- BRC & ISO & FDA Approved

- Stylish stand up, less material to fill more products

- Sustainable

Do You Want To Distinguish Your Brands With A Recyclable Packaging?

100% Recyclable Flat Bottom Pouches

Peoples are paying more attention on the environment today. That’s why we need 100% fully recyclable flexible packagings. These will help us save more resources.

Our 100% Recyclable High Barrier Mono Material PE Flat Bottom Pouches are the best solution of flexible packaging recyclability. It can meet the recyclability of below standards:

- CE FLEX in EU

- How2Recycle in USA

- REDcycle in Australia

- SOFT PLASTIC in New Zealand

Request Free Samples

Looking for a win-win business relationship?

We will always be your reliable 100% recyclable flexible packaging partner to work with!

What is Recyclable Flat Bottom Pouch? Your Ultimate Guide

1) What is Flat Bottom Pouch?

A flat bottom pouch is a five-sided, stand up pouch with a flat, rectangular base. This premade pouch is printable with five panels are perfect for on-shelf brand building. It provides superior stability, seal strength, and hermeticity compared to other pouches.

A flat bottom pouch is also called box pouch, flat base pouch or block bottom pouch.

2) What is Recyclable Flat Bottom Pouch?

Recyclable flat bottom pouch is the flat bottom pouch made with recyclable film materials. Normally it is made by mono-material which is 100% fully recyclable. Currently the possible materials are PE and PP. The main film structures as below:

Standard: MDO-PE/PE, PP/PP

Barrier: High Barrier MDO-PE/PE

3) Flat bottom pouch Customized varieties

Transparent:

For 100% high barrier mono material PE laminated film, it is all transparent. So basically you can make the side gusset transparent, it will also have high barrier functions. Or you can leave the front design with a window, this will also no infection on the barrier function. While the customer can see through the packaging, this is good for marketing.

Handles and Pouch holes

You can put either handles or pouch holes on top of the pouch. So the flat bottom pouch can hook on the shelf, this is also good for pouch on shelf. So besides stand on the shelf, the pouch can also be hooked on the shelf.

Laser scoring

Laser scoring will make it easier for customer to tear open the pouch.

Normally it will be place on the top of the pouch, while below the heat sealing part.

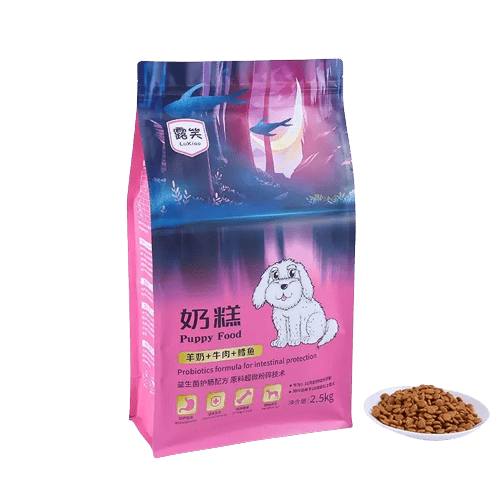

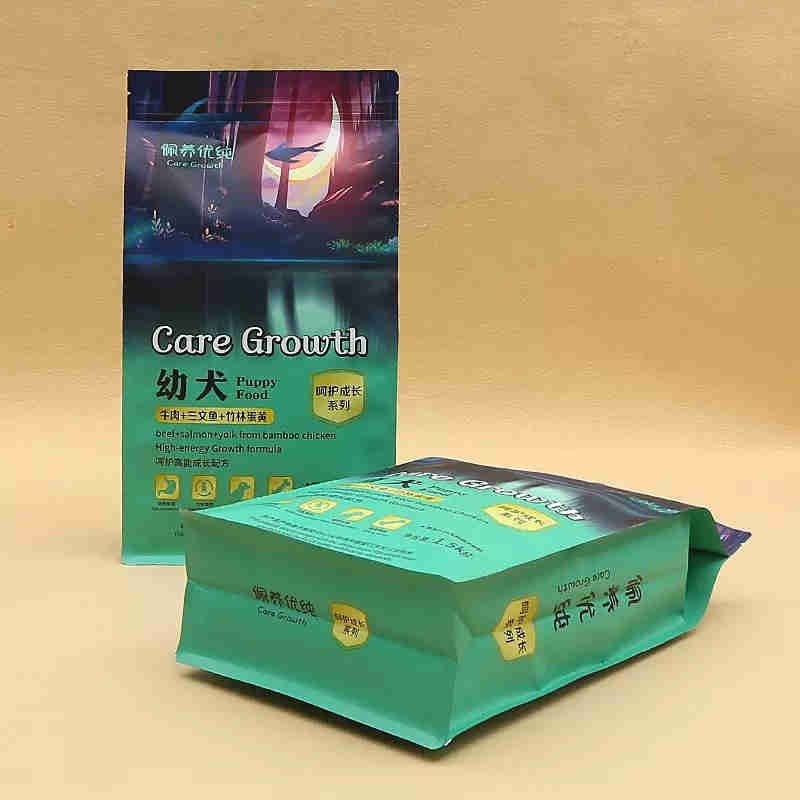

Sliders and zippers

You can put sliders on the top, this will be often seen from pet food flat bottom pouch. Such as dog food, cat food, horse food, etc. It is usually for the packed products with bigger capacity so we can always close it with slider after we take out the part we need.

There are two kinds of zippers. The first one is the same press and open zippers as the basic standard pouch. It will close well, but the opening hole is not the big as the Rippa Zippa pouch which is open on the front. The Rippa Zippa pouch is with a very big opening hole for product filling, and it will also have the zipper function for product usage by customers.

Matte and gloss finishing

We can always see matte and gloss finishing for many designs. It will make the overall artwork looks more beautiful. Or you can have all matte finishing or all gloss finishing, it is always up to you to follow your design strategy.

Valve

Valve is particularly for coffee packaging. Coffee is the most important drinks for many countries. In order to keep the flavor, we will need valve on the coffee bag.

Normally there 3 types of valve:

WIPF

Goglio

And Chinese valve.

The valves can be all PE material or PP materials, so fit for the PE or PP mono material pouch material.

Tin Tie

Tin Tie will be used to fold the bag after we use it for the first time, until we finished consume all the fill products. It is often seen in the coffee bags.

4) Benefits of Recyclable Flat Bottom Pouch

Recyclability

Sustainability is so important for packaging today. There are so many waste cause by packages. No doubt that packaging is one of the biggest sources of resources waste. That’s why we need 100% fully recyclable flexible packaging. Then we can re-use the resources again and again. So we can consume less raw materials while can make more products.

Five panels printable

Flat bottom pouch is the only bag style that have 5 panels printable. In this case you can see the design no matter which side you are looking at the pouch. This is good for marketing and branding.

Stable standing on shelf

The biggest advantages of flat bottom pouch is it can stand on the shelf stable. The flat base will make sure it can stand up well. As we know the basic stand up pouch can stand on the shelf. But flat bottom pouch is much better in standing. No too mentioned you can also see the side design when it stand on the shelf.

Less film needed

Flat bottom pouch can fill more products than other bag styles. We have done test before, flat bottom pouch can save 20% materials to pack the same products when comparing to other bag styles.

High Barrier

The flexible barrier materials can make Flat barrier pouch. So it is not only flat bottom packaging, it is also high barrier flat bottom pouch.

5) What are the materials for recyclable flat bottom pouch

MDO-PE/PE

This is the standard film structure. It is fully recyclable, but not with the barrier function.

High barrier MDO-PE/PE

This is the high barrier film structure. It can be OTR 0.5, WVTR 1.

As we all know there are so many products needed high barrier function flexible packaging. Such as food packaging, medical packaging, etc.

Actually it is not difficult for us to have standard recyclable packaging. It comes out from the market many years ago. But only these 2 years we have barrier function on fully recyclable packaging. This is the packaging revolution, and this is the final solution for flexible packaging recyclability.

6) Applications

Like stand up pouch and other bag styles. Flat bottom pouch can be used to pack most of the products. Actually more and more companies are choosing flat bottom pouch for it is stability and better marketing. It is a perfect bag solution for the products which will put on shelf.

Normally it can be with food and non-food packaging. It is good for storing, stocking, shipping and store shelf selling.

For food, included: coffee, tea, cereals, pet food, snack, candies, etc. ( recyclable food packaging)

For non-food: it can with pharmaceutical product, medical product, industrial product,

7) Production and artwork

The flat bottom pouch production is the same as other bags, you design the artwork, prepare the material, blow the film, print it, laminated, and then bag converting. It can only come with preformed pouches.

For artwork, one thing very important is it will need 2 pieces of films while the other packagings only need one. The front, bottom and back share one piece of film, and the left gusset & right gusset share one piece of film. Which means you will need to make artwork design for 2 pieces of films. Included 2 sets of printing plates.

Conclusion

Recyclable flat bottom pouch is one of the most popular laminated flexible packaging today. It is sustainability and stability will make sure it is superior advantages when comparing to other packaging. For sure we will see more and more this packaging in the market.

What Longdapac can help?

Longdapac is the leading flexible packaging manufacturer from China since 1991. We focus on sustainable flexible packaging as you can see below:

Longdapac is the first high barrier MDO-PE film manufacturer in China and it is the first high barrier mono-material PE pouch manufacturer in China. ( MDO-PE / PE and MDO-PE / High barrier MDO-PE / PE)

Longdapac recyclable high barrier mono-material PE pouches can meet the recyclability of:

- CE FLEX in EU

- How2Recycle in USA

- SOFT PLASTIC in New Zealand

- REDcycle in Australia

Longdapac is a BRC and ISO certified factory with annual capacity of more than 25,000 tons.

Basically Longdapac can satisfy all your recyclable flexible packaging needs, both standard and high barrier.