How Recyclable Flexible Packaging Achieves High Barrier Performance

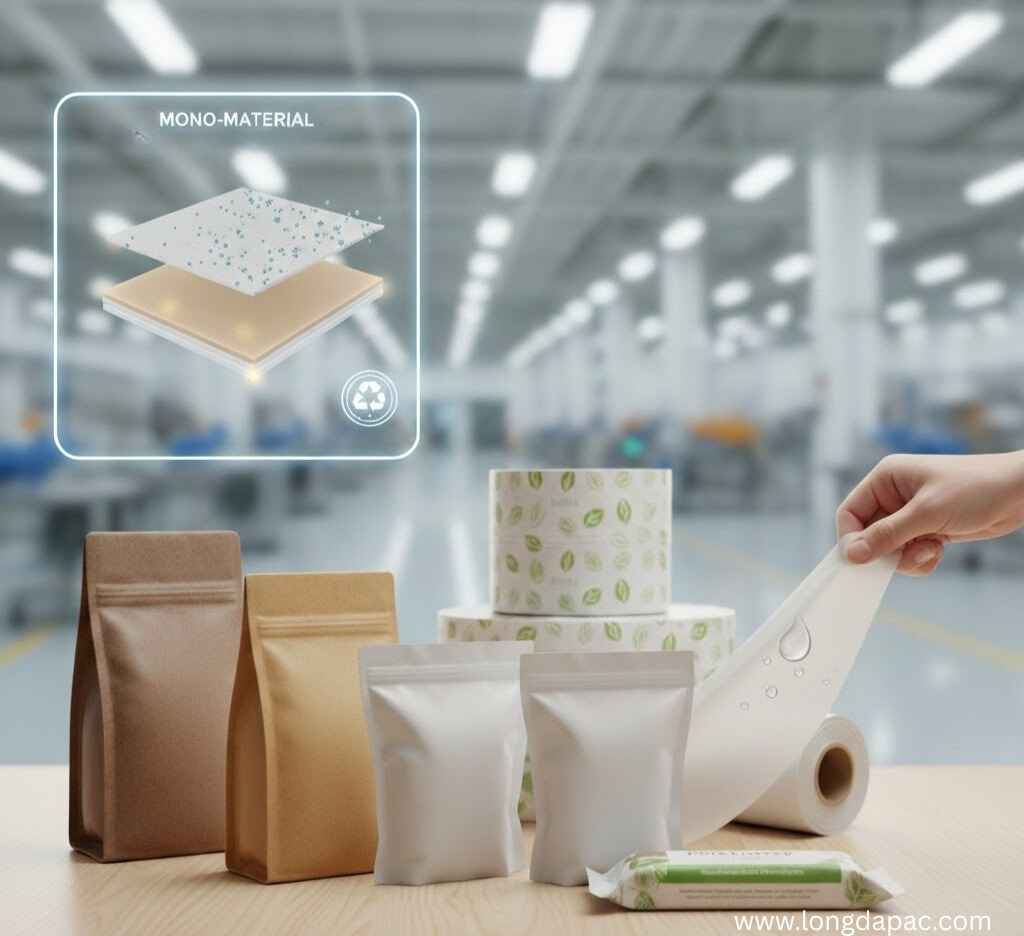

Packaging is important for keeping products safe, fresh and high quality from production to consumption. As awareness of environmental issues grows, businesses are seeking packaging solutions that are both effective and sustainable. Recyclable flexible packaging has become a practical choice, offering strong protection with eco-friendly properties. Unlike conventional flexible packaging, which cannot be recycled because of laminated layers of different materials such as PET and PE, recyclable flexible packaging uses a single material structure, while maintaining performance.

Recyclable flexible packaging also meets modern requirements for durability, flexibility and high barrier performance. Barrier properties are important for protecting products from moisture, oxygen, light and other external factors that can affect quality and shelf life. This blog explains how recyclable flexible packaging achieves high barrier performance by focusing on material selection, layer design and innovative manufacturing techniques. Readers will gain a clear understanding of why this packaging is a sustainable, efficient and practical solution for current industries.

In this article, we will guide you on how recyclable flexible packaging protects products and supports environmental sustainability. We will also cover key differences from conventional packaging, materials and design strategies, and practical applications for high barrier performance.

Structure of Recyclable Flexible Packaging

Recyclable flexible packaging is made with mono-material layers, meaning all layers use the same type of polymer, usually polyethylene (PE) or polypropylene (PP). Multiple layers of the same material can be combined to provide strength, barrier protection and sealability. Unlike conventional flexible packaging, which cannot be recycled because of laminated layers of different materials, mono-material structures allow full recyclability.

Each layer has a specific role: the outer layer gives mechanical strength and printability, the middle layer improves barrier performance and the inner layer ensures seal integrity. Combined, these layers protect the product while staying fully recyclable.

This design also offers durability and flexibility. Recyclable flexible packaging can withstand stretching, folding and compression without losing its barrier properties. This makes it suitable for a wide range of products such as food, personal care and pharmaceutical items.

Why Conventional Flexible Packaging Cannot Be Recycled

Conventional flexible packaging is often made by laminating different materials, such as PET/PE or PET/ALU/PE. While these laminates offer strong barrier protection, they cannot be recycled because the different polymers cannot be separated. Once these layers are bonded, they cannot enter standard recycling systems and often end up in landfills.

This limitation has driven the industry toward mono-material alternatives. Recyclable flexible packaging addresses environmental challenges without compromising barrier performance. It combines sustainability and functionality, offering brands an opportunity to meet growing regulatory and consumer expectations for eco-friendly packaging.

Layer Design Techniques

Layer design is essential for high barrier performance.

Each layer serves a specific purpose:

- Outer layer: Provides strength, durability and printability

- Middle layer: Protects against oxygen, moisture and light

- Inner layer: Ensures seal integrity and product safety

The thickness and order of layers are carefully designed. Thicker middle layers improve moisture and oxygen resistance, while thinner outer layers reduce material use and cost. This design allows recyclable flexible packaging to perform similarly to conventional laminates.

Well-designed layers also increase durability. The packaging can resist punctures, tears and stretching during transportation and handling, making it suitable for different types of products.

Choosing the Right Material

Material selection is the first step in achieving high barrier performance. Polyethylene (PE) is the most commonly used material, making up over 90% of recyclable flexible packaging, while polypropylene (PP) accounts for about 10%. Both provide moisture and oxygen resistance while staying fully recyclable.

PE is flexible, cost-effective and offers excellent moisture barrier properties. PP is used when higher heat resistance is needed. Choosing the right material grade, thickness and formulation allows manufacturers to achieve barrier performance similar to conventional laminates without affecting recyclability.

Additives can also improve barrier performance, such as oxygen scavengers or moisture blockers. These are added to mono-material layers, ensuring recyclable packaging meets performance standards while remaining eco-friendly.

Light and UV Protection

Recyclable flexible packaging also protects light-sensitive products such as oils, vitamins and beverages. Pigmented or opaque layers block UV and visible light, while the arrangement of layers ensures maximum protection.

- Prevents nutrient loss and color degradation

- Preserves product quality and shelf life

- Pigments or coatings maintain the barrier while keeping packaging recyclable

- Supports environmentally responsible packaging choices

This combination of layers, pigments and coatings keeps products safe and high-quality, showing that mono-material packaging can provide complete light protection.

Shelf Life Extension

Recyclable flexible packaging extends the shelf life of sensitive products. Its carefully designed layers protect against moisture, oxygen and light, keeping food, beverages and pharmaceuticals fresh and high-quality.

Layer thickness and polymer choice are tailored to specific product needs, providing optimal protection without extra material or cost. This ensures consistent quality from production to consumption.

Longer shelf life also improves distribution and storage. Products can withstand longer transit times and varying conditions without spoilage, reducing waste and increasing operational efficiency.

Mechanical Strength

High barrier packaging must also withstand physical stresses. Recyclable flexible packaging is designed to be flexible yet durable, resisting tears, punctures and stretching. This ensures safe transport, handling and compatibility with automated packaging systems.

- Resists tears and punctures for safe handling

- Flexible for easy processing on packaging lines

- Maintains durability during shipping and storage

- Suitable for different product types without damage

Strong and flexible packaging ensures reliable performance across various products and environments.

Environmental Impact Reduction

Recyclable flexible packaging greatly reduces environmental impact compared to conventional multi-material laminates. Its mono-material layers allow efficient recycling and reduce landfill waste. Resource use and energy consumption are optimized during production, helping lower carbon emissions.

The packaging design also supports sustainable sourcing. Manufacturers can use responsibly produced polymers or recycled content without affecting barrier performance. This encourages a circular economy where materials are reused, reducing the overall environmental burden.

Brands that use recyclable flexible packaging can meet regulatory requirements and enhance their sustainability profile. This shows a commitment to environmental responsibility and strengthens consumer trust and brand image.

Oxygen Barrier Strategies

Recyclable flexible packaging protects products from oxygen, which can lead to spoilage, oxidation and reduced quality. By choosing the right polymer grades and designing multiple mono-material layers, manufacturers achieve strong oxygen resistance. The correct combination of PE or PP layers lowers oxygen permeability while keeping the packaging fully recyclable.

- Multiple PE or PP layers effectively block oxygen

- Specialized low-permeability grades increase protection

- Food-safe additives such as oxygen scavengers can be added

- Helps maintain product freshness and extend shelf life

The result is a recyclable packaging solution that provides oxygen barrier performance similar to conventional laminates, ensuring product safety while remaining sustainable.

Compatibility with Modern Printing

Mono-material films work well with advanced printing techniques, allowing brands to add vibrant graphics and messaging directly onto recyclable packaging. Surface treatments improve adhesion while keeping barrier properties intact.

This makes it possible to clearly display product information, logos and promotional designs, attracting consumers while maintaining packaging functionality.

Printing does not reduce performance, so recyclable packaging stays protective and visually appealing, meeting both marketing and product safety requirements.

Adaptability to Different Product Forms

Recyclable flexible packaging easily adapts to different product formats, including pouches, bags and sachets. Its flexible structure allows precise shaping while keeping barrier protection intact.

Resealable options or zippers can be added without affecting the mono-material structure, supporting repeated use and consumer convenience.

This adaptability also improves automated packaging processes, reducing downtime and increasing efficiency while maintaining high-quality protection for a variety of products.

Enhancing Moisture Barrier

Moisture protection is essential for food, pharmaceuticals and other sensitive products.

Recyclable flexible packaging provides this through:

- Optimized layer thickness to reduce water vapor transmission

- High-quality PE or PP grades with natural moisture resistance

- Surface treatments or coatings that enhance barrier performance

The multi-layer mono-material structure keeps products fresh and safe while maintaining flexibility and strength.

Cost Efficiency in the Long Term

Despite being slightly more expensive than conventional laminates, recyclable flexible packaging provides long-term cost benefits. Reduced waste disposal, potential recycling credits and simplified production processes help offset upfront expenses.

Using recycled or responsibly sourced polymers can lower production costs without compromising quality. Simplified mono-material structures reduce complexity and labor requirements.

Over time, recyclable flexible packaging offers both financial and environmental advantages, making it a practical investment for businesses focused on sustainability and profitability.

Heat Resistance

Recyclable flexible packaging must endure heat during storage and transport. Using materials such as PP and engineered PE layers, it maintains seal integrity and structural strength even with temperature changes.

- Heat-resistant materials prevent deformation

- Strong seals maintain product protection

- Withstands temperature changes during transit and storage

- Suitable for food, pharmaceutical and personal care applications

The design ensures that products remain safe while maintaining packaging recyclability.

Regulatory Compliance

Mono-material recyclable packaging helps companies comply with increasing global environmental regulations. Many regions now require packaging to be recyclable or to meet sustainability targets. Using recyclable films allows businesses to meet these standards without reducing protection.

Manufacturers can provide documentation and certification for the materials used, showing compliance and transparency to consumers.

Adopting recyclable packaging also helps companies avoid penalties while enhancing brand reputation, aligning operations with regulatory requirements and sustainability goals.

Practical Applications

Recyclable flexible packaging is used in many industries because of its barrier performance and sustainability.

- Food: Snacks, dry foods, frozen goods, beverages

- Personal care: Shampoos, lotions, wipes, soaps

- Pharmaceuticals: Capsules, powders, medical devices

- Household products: Cleaning items, detergents, wipes

This packaging keeps products fresh, safe and high-quality while supporting environmental responsibility. It combines durability, barrier performance and recyclability, making it an ideal choice for modern industries.

Integration with Smart Packaging

Recyclable flexible packaging can include smart features such as QR codes, NFC tags or freshness indicators. These features provide product information or monitoring without affecting barrier performance or recyclability.

Smart integration boosts consumer confidence, allowing them to track product freshness or verify authenticity. Manufacturers also gain insights for supply chain optimization and waste reduction.

In addition, the mono-material construction ensures that smart elements do not interfere with recycling, preserving the environmental benefits of the packaging.

Brand Value Enhancement

Using recyclable flexible packaging enhances brand perception. Consumers prefer products packaged sustainably, associating mono-material, eco-friendly solutions with quality and responsibility.

Professional printing and smooth finishes improve shelf appeal while reinforcing brand identity. Combining sustainability with strong barrier performance communicates reliability and care for both products and the environment.

This investment strengthens customer loyalty and positions the brand as forward-thinking, meeting consumer demand for environmentally conscious choices.

Future Prospects and Innovation

The future of recyclable flexible packaging depends on continuous innovation. New materials and improved layer design increase strength, flexibility and barrier performance, making mono-material packaging suitable for more applications.

Trends include integration with smart technologies, enhanced recyclability and customized barrier solutions for specialized products. These advancements expand packaging possibilities while reducing environmental impact.

As consumer and regulatory demand for sustainable packaging grows, recyclable flexible packaging is set to become the leading solution for high-performance, eco-friendly product protection.

Conclusion

Recyclable flexible packaging provides a sustainable, high-performance solution for protecting products in food, personal care, pharmaceutical and household industries. It offers strong barrier protection against moisture, oxygen and light while remaining durable, heat-resistant and mechanically strong. Unlike conventional multi-material laminates, mono-material designs support environmental responsibility, regulatory compliance and a circular economy. Its flexibility for different product forms, compatibility with modern printing and ability to include innovative features make it practical and visually appealing, helping brands maintain quality, extend shelf life and build consumer trust while contributing to a sustainable future.

Longdapac is the leading recyclable mono-material PE pouches factory in China. We have been making recyclable pouches from 2020. The most important part in this pouch is the high barrier function. Currently we have EVOH, METAILIZED, PVOH, ALOX, SIOX, ETC for the high barrier function. We can say we meet 99% of the high barrier demand in the market.

Frequently Asked Questions

Q1: What makes recyclable flexible packaging different from conventional flexible packaging?

Answer: Recyclable flexible packaging uses mono-material layers such as PE or PP, allowing it to be processed in recycling systems. Conventional multi-material laminates cannot be recycled, making recyclable packaging a more sustainable option.

Q2: Can recyclable flexible packaging provide the same protection as traditional packaging?

Answer: Yes, it provides strong barrier protection against moisture, oxygen and light, along with durability and heat resistance. Products stay fresh and safe, performing on par with conventional laminates.

Q3: Is recyclable flexible packaging suitable for all product types?

Answer: Yes, it can be used for food, beverages, personal care, pharmaceuticals and household products. Its flexible structure adapts to different packaging formats without reducing barrier performance.

Q4: Does recyclable flexible packaging affect shelf life and product quality?

Answer: It helps extend shelf life by protecting products from environmental factors such as moisture, oxygen and light. Products stay fresh and maintain taste and quality during storage and transport.

Q5: Why should businesses choose recyclable flexible packaging?

Answer: It combines sustainability, high performance and regulatory compliance. Unlike conventional laminates, which cannot be recycled, it protects products while boosting brand value and supporting environmental responsibility.