Ultimate Guide: New Thresholds 2023 of Packaging Recyclability from REDcycle, APCO & PREP

On April 13 2022, APCO sent an email to all its members that they will published an updated version of the Quickstart Guide for designing household consumer soft plastics for recyclability. This Guide provides the thresholds for design that will be live in the Packaging Recyclability Evaluation Portal (PREP) in June 2023.

This new version guide with so many big changes; which makes most of the recyclable packaging before and not recyclable anymore today.

In this email we will give you an ultimate guide on the new thresholds published in 2023 of packaging recyclability from APCO, PREP & REDcycle.

It’s an in-depth article that takes 30 minutes to read.

Navigation, click to jump to the section you want to read

Ultimate Guide: New Thresholds 2023 of Packaging Recyclability from REDcycle, APCO & PREP

1)What is APCO?

The Australian Packaging Covenant Organization (APCO) is a not for profit organization leading the development of a circular economy for packaging in Australia.

Their vision is a packaging value chain that collaborates to keep packaging materials out of landfill and retains the maximum value of the materials, energy and labor within the local economy.

They work with governments, businesses and other organizations from across Australia’s large and complex packaging value chain to develop the insights, resources and programs that are needed to build a sustainable national packaging ecosystem.

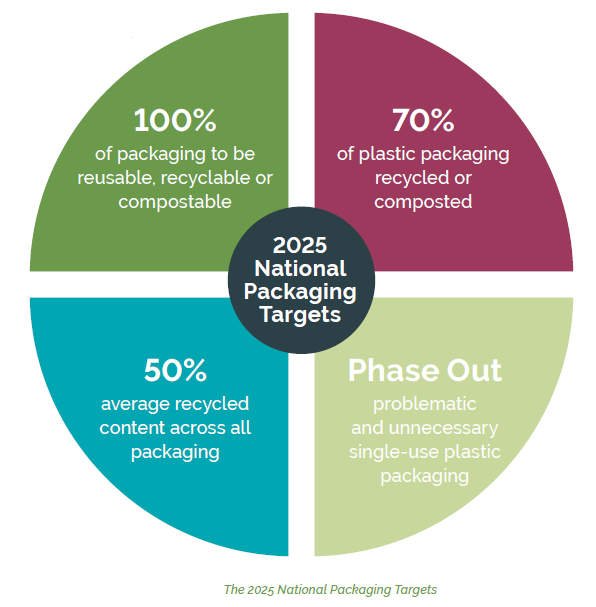

This includes facilitating the delivery of Australia’s 2025 National Packaging Targets, an important step on the pathway to a circular economy.

2018 Result in Australia. So we can see there is a long way to go.

2) What is PREP?

The Packaging Recyclability Evaluation Portal (PREP) is an online platform organizations are able to use to verify if their packaging is or isn’t recyclable in Australian and New Zealand curbside collections.

When it comes to packaging, even the smallest details can have an impact on recyclability, including the packaging shape, size, weight, inks, adhesives and the materials used. For every item of packaging, PREP considers all of these factors, as well as the availability of collection services, how the packaging will behave in a Materials Recovery Facility (MRF) and in subsequent processing facilities, such as paper mills and aluminium smelters.

By aggregating all of this information into a simple online platform, PREP enables businesses to understand whether their packaging is recyclable, non-recyclable, or conditionally recyclable – provided consumers follow a set of instructions during disposal.

The PREP process provides a verified and transparent education loop between the design and the end-of-life of packaging in the Australian and New Zealand kerbside recycling systems.

How to use PREP

3) What is ARL?

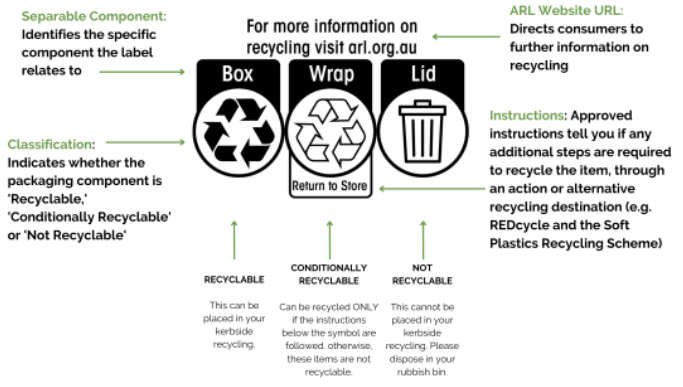

The Australasian Recycling Label (ARL) Program is an on-pack labelling scheme that is helping consumers to recycle correctly and supporting Brand Owners and packaging manufacturers to design packaging that is recyclable at end-of-life.

The Program features two key elements:

- The Packaging Recyclability Evaluation Portal (PREP) – an online tool that assesses packaging recyclability in the Australian and New Zealand kerbside or approved drop-off recycling systems.

- The Australasian Recycling Label – an on-pack label that provides clear and simple instructions about how to recycle all of the separable packaging components.

The ARL Program has been acknowledged in the National Waste Policy Action Plan and National Plastics Plan as a key action to improve consumer awareness and increase recycling rates. As part of the National Plastics Plan, the Australian Government has committed to working with industry to see the ARL displayed on 80% of supermarket products by 2023.

What is ARL

ARL explanation

4) What is REDcycle?

RED Group is a Melbourne-based consulting and recycling organisation who has developed and implemented the REDcycle Program; a recovery initiative for post-consumer soft plastic.

We have teamed up with Coles, Woolworths and some of Australia’s most-loved brands to make it easy for you to keep your plastic bags and soft plastic packaging out of landfill.

The REDcycle Program is true product stewardship model where manufacturers, retailers and consumers are sharing responsibility in creating a sustainable future. See our partners page to see which of Australia’s most-loved brands are on board to reduce the amount of plastic packaging going to landfill.

5) What is CE FLEX?

The Circular Economy for Flexible Packaging (CE FLEX) initiative is a collaboration of over 180 European companies, associations and organisations representing the entire value chain of flexible packaging. Together, we work to make all flexible packaging in Europe circular by 2025.

CE FLEX’s ‘Mission Circular’ commits to collection of all flexible packaging and over 80% of the recycled materials channelled into valuable new markets and applications to substitute virgin materials

A 5-step roadmap to build a circular economy for flexible packaging has been endorsed by CE FLEX stakeholders, together with a set of actions needed by each part of the value chain to make it happen.

By 2025, we target an established collection, sorting and reprocessing infrastructure and economy for post-consumer flexible packaging across Europe. It will be based on end-of-life technologies and processes which deliver the best economic, technical and environmental outcome for a circular economy.

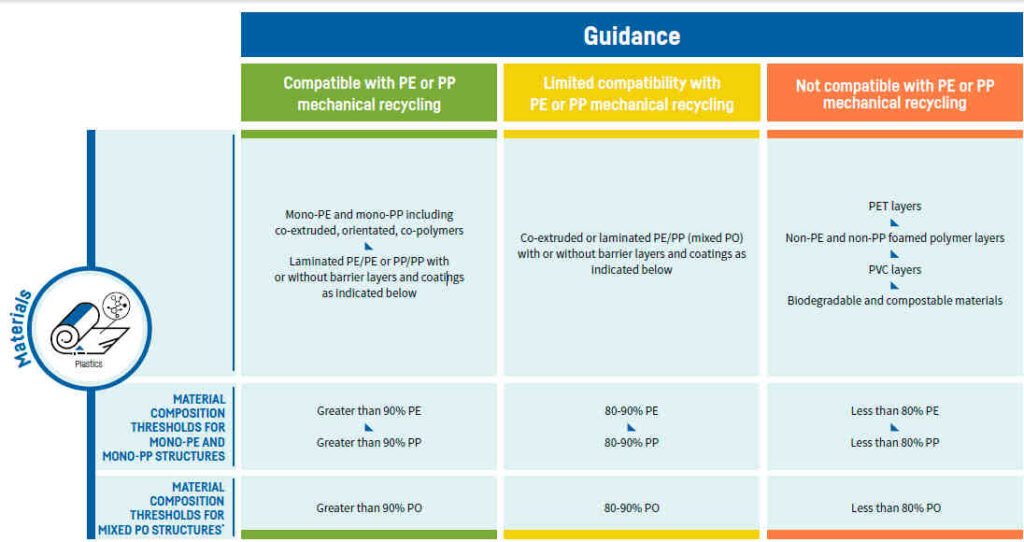

Note: As we can see from above, PET layers are not compatible with PE or PP mechanical recycling, so PET is prohibited to maximum 0%.

6) The old version of thresholds of soft plastics recyclability 2011 to 2022

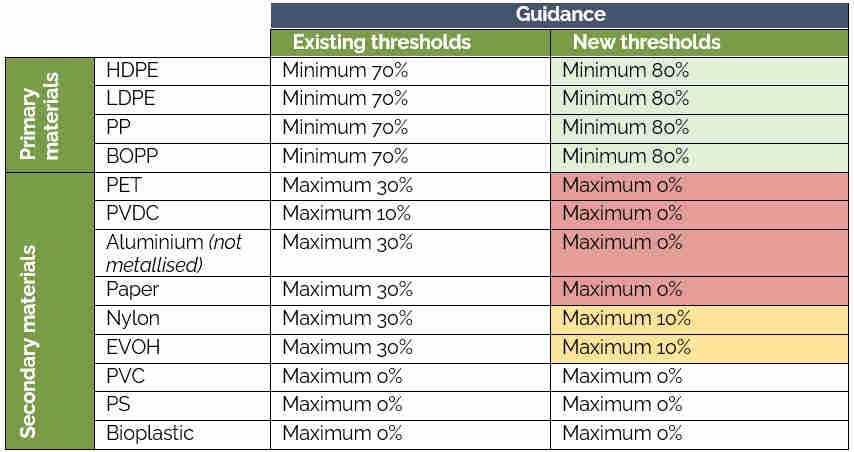

As we can see from above 2 guidances, PET, foil are allowed with Maximum 30%

7) The updated version of thresholds of soft plastics recyclability 2023 to 2030

8) Key differences on new version thresholds

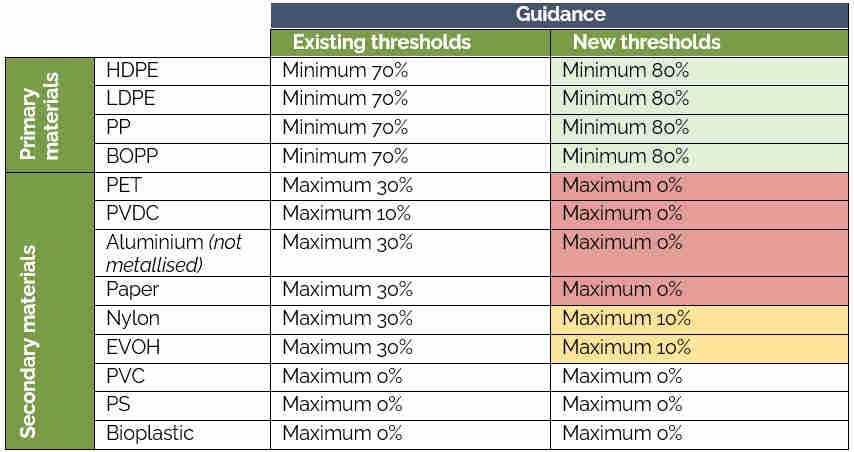

Key changes and a summary of the updates are included below:

- For primary materials, the polyolefin content has increased from a minimum of 70% to 80% (green);

- Importantly, PET, PVDC, Paper and Aluminium (not including metallised layers) are not accepted at any percentage inclusion (red);

- Nylon and EVOH have decreased from 30% to 10% inclusion (yellow).

- PVC, PS and Bioplastics/compostable plastics remain unacceptable at any percentage inclusion (white).

9) Impact of new version thresholds

There will be no difference if your current packaging is one layer only, this will be recyclable for sure.

If you are using laminate pouch, and it will be big difference. As a matter of fact, the main focus is multilayer pouch when talking about soft plastics recyclability.

Laminating pouch is using to solve 2 packaging problems:

1: Weight (The product filled in the pouch is heavy so need thicker material)

In order to be with thicker material, the best way is to laminate 2 or more layers of film and make the total final film thick enough to pack the products.

Normally it can be with below film structure:

BOPP/CPP

BOPP/PE

PET/CPP

PET/PE

PET material is much more stable than BOPP so it is been widely used in the soft plastics. As you can see from above PET is allow to be no more than 30% and now prohibited to Maximum 0%.

But this is easy to solve, we can just use BOPP/CPP and this is still recyclable for new version thresholds.

Or you can use MDO-PE film and make it MDO-PE/PE film structure to solve this product. This is mono-material structure.

2: Barrier (The product filled in the pouch need to protect from Oxygen and water vapor)

High barrier function is so important for below:

OTR (oxygen transmission rate)

WVTR (water vapor transmission rate)

With high barrier function on the film will keep OTR and WVTR low. So the packed products can stay fresh and good quality after a longtime in shelf. Let’s say 6 to 24 months.

This is important for:

Food bags

Coffee bags with valve

Tea bags

Pet food bags

Rice bags

And all kinds of pouches that need high barrier film for production. No matter it is flat bottom bags, box bottom pouches, stand up pouches, stand up pouches with window, quad seal stand up pouch, side gusset bags and flat bags.

In old version, the most common film structures are below:

BOPP/VMPET/PE

PET/VMPET/PE

BOPP/foil/PE

PET/foil/PE

VMPET and foil are the films act as high barrier function. We should say these 2 materials are very good for high barrier packaging and it protects the products well.

Note: It can also metalized film of MOPP, MCPP, but no that popular as VMPET (metalized PET)

But as you can see from the new version thresholds, PET and foil are prohibited with maximum 0%. It means no more PET and foil will be allow to use in recyclable pouches. If want to do with sustainable food packaging pouches and environmental friendly pouches, you will have to give up VMPET and foil in order to make eco friendly pouch bags.

In this case, it will need bag suppliers, pouch manufacturers, soft plastics wholesalers and packaging providers to find a new way: both recyclable and high barrier protection.

10) Best Solution of this new version threshold soft plastics recyclability

Some bag suppliers may use EVOH, this can meet the recyclability requirement, but EVOH is not the same material as primary material (PE), and the cost is very high.

So the best solution is use mono material pouch. Single layer material can called mono material; while multiple layers of the same material can be considered as mono-material also.

Here is the best recycle pouch film structure:

PE/PE (The surface PE layer is with high barrier treatment)

In this case the High Barrier PE/ PE can replace VMPET and foil as the high barrier function. While the mono-material structure can fully recyclable.

11) Longdapac: The high barrier recyclable pouch manufacturer

Longdapc is the leading high barrier recyclable pouch supplier from China. The factory makes 25,000 tons of laminating packaging per year. Of which more than 10 million pouches are recyclable laminate pouches.

Longdapac is the first Chinese factory with high barrier mono-material recyclable pouch in China. With high barrier treated PE/PE film structure, this will guarantee the recyclability of the pouch. We are not talking about 80% primary material PE (recyclable with reduce value). we are not talking about 90% primary material PE (preferred), we are talking about 100% same material PE. This is the best film structure for recyclable pouch.

So we can say Longdapac is the answer for high barrier recyclable pouch.

This article is written by Longdapac, ( www.longdapac.com), leading recyclable high barrier pouches manufacturer from China.

Please contact Longdapac for a free quote on your recyclable flexible packaging needs. We have quick response, efficient communication, quality products, on time delivery, and competitive price.