How to Buy Custom Print Flexible Packaging From China

What is flexible packaging

Flexible packaging is a means of packaging products through the use of non-rigid materials, which allow for more economical and customizable options. It is a relatively new method in the packaging market and has grown popular due to its high efficiency and cost-effective nature. This packaging method uses a variety of flexible materials, including foil, plastic, and paper, to create pouches, bags, and other pliable product containers. Flexible packages are particularly useful in industries that require versatile packaging, such as the food and beverage, personal care, and pharmaceutical industries.

It can be single layer & multi laminated layer packaging. Die cut shopping bag and trash bag are single layer bag. While bags need higher protection and high barrier will need multi-layer such as coffee bag, tea bag, pet food bag, etc.

For most of the people, they know it is cost saving to buy flexible packaging from China, but they don’t know how to do it.

In this article, we will talk about how to buy custom print flexible packaging from China.

It’s an in-depth article that takes 20 minutes to read.

Navigation, click to jump to the section you want to read

How to Buy Custom Print Flexible Packaging From China

1) Preparation before buying

Before you order any packaging from China, I am sure you will know what packaging exactly you need; or at least you know what you want to pack, such as pet food, snack, coffee or tea.

Below we will list some of the info needed before you make the order.

Bag Material:

You already know what material you need: Such as: PET/PE, PET/VMPET/PE, PET/AL/PE, BOPP/PE, BOPP/VMPET/PE, BOPP/AL/PE, etc.

Or if you don’t know the exactly material you need, but you have bag samples, then you can simply send the bag sample to factory to quote.

In the case you don’t know what material you need, and you don’t have any samples. You can tell the factory what product you need to pack, and the factory will recommend the bag material to you.

Bag style:

You already know what bag style you need, and then just tell the factory directly. Such as stand up pouch, side gusset bag, box bottom pouch, flat bottom pouch, 3 side seal bag, etc. And also special requirements on the bag if needed: Spout, zipper, valve, tin tie.

If you don’t know how to call the bag, but you have a sample, you can simply take a picture, and send to factory, that will be good too.

In case you don’t know what bag styles you need, and you don’t have any sample available, then you can ask the factory for recommendation, what you need to do is tell the factory what you need the packaging to pack.

Bag Size:

You will need to know the size of the bag you need. Such as 50g, 100g, 200g, 250g, 500g, 1kg, 2kg, 5kg, etc.

Quantity

Quantity is very important, you will need to make a forecast on the quantity of bags you need.

Artwork

If you don’t need any printing on the packaging, that’s fine.

But you will need to prepare artwork if you need custom print.

You can send directly to factory if you already have artwork.

You can take a picture and send to factory that will be also ok for a quote.

Or you can just simply tell the factory how many colors you need on the packaging, and percentage of the printing it will be.

2) Enquiry

When you have all the preparations ready, you can start to get price for it.

There are lots of ways to find flexible packaging suppliers from China.

You can send it directly to your supplier if you already know some suppliers.

You can ask your friends for recommendation if they just happen to know packaging suppliers from China.

You may Google, and select the comfortable supplier and send your enquiry.

You can go to some B2B websites for quote, such as alibaba.com, indiamart.com, Chinasourcing.com

You can also go to some famous packaging exhibition if possible, and you can find some suppliers from there.

When you receive the quotes, you can judge the supplier from below:

Profession: when you communicate with the factory, you should have idea some of the factories are very profession, they can understand what you need, and provide correct info to you.

Price: Select the price which can meet your target price. (Note: if you ask many factories for quotation, please make sure you are selecting the most reliable price; not somebody who are quoting sky high, or unbelievable low)

You will also need to consider the service, payment terms, lead time delivery, quality, and factory size.

3) Order placing

When you choose the right supplier after enquiry, you are ready to quote.

Please finalize all the details of below:

Bag material

Bag style

Bag size

Quantity

Artwork

Artwork will be very important, and you will need to prepare artwork base on the die cut from the factory.

You can either ask your designer to adjust it and send to supplier.

You can ask third party design company locally to do the artwork.

You can ask the factory to recommend a designer company to do it.

When all the details are ready, you can place official order to the factory now.

4) Production

Now the order comes into production.

The factory will follow below production process:

Raw material sourcing: they will either source resin or film outside.

Film making: they will blow the film if needed. Big factories always have their own PE film blowing workshop.

Printing: There are 3 printing process mainly

Rotogravure: The factory will need to make printing plate first, and then print on the film The printing quality is the best for rotogravure, but it need more professional skills to check the color. This is the main printing process from China. More than 95%.

Flexo printing: This is normally using in western countries cause it needs less profession. No printing plate needed. You can simply supply the artwork in the computer, and check the data carefully; it will be ready to print.

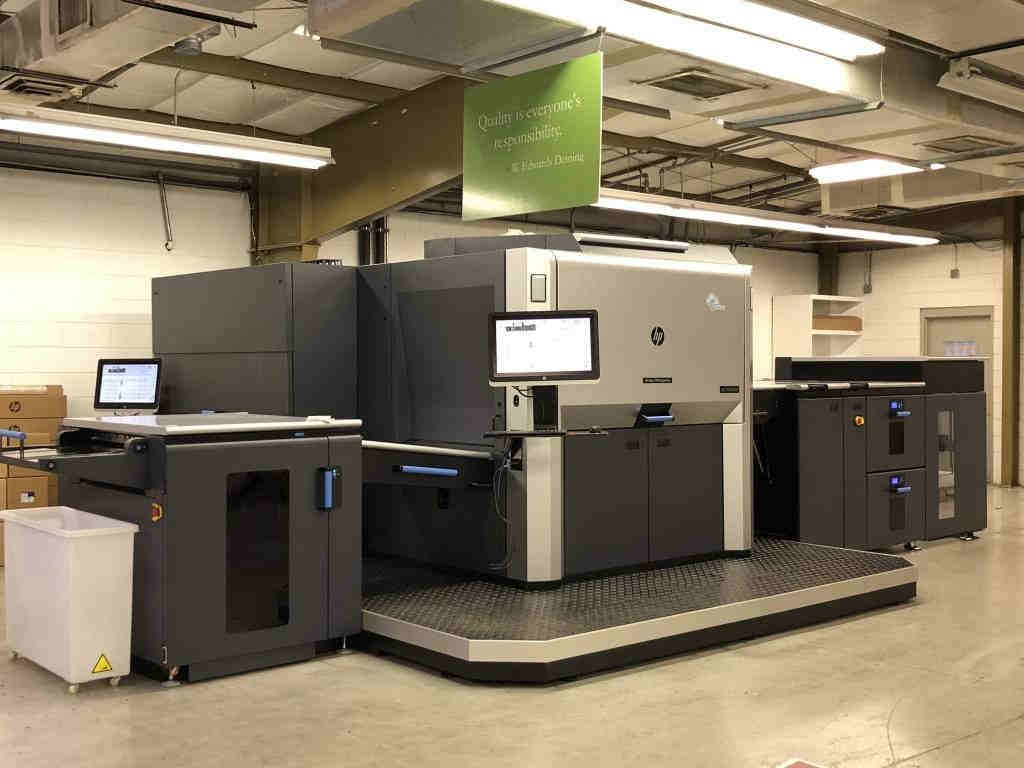

Digital printing: This is normally for small quantity. It will print on the film directly. HP Indigo 12000 Digital Press is making this technology perfect.

Lamination: The lamination machine will laminated each film layer together.

Aging: The laminated film will be aging for 48 hours and make sure the lamination quality is good.

Bag making: The machine will make the bag from the laminated film.

Packing: Pack the bag in carton boxes and palletized if needed.

5) Quality check

Quality check is always very important. We will need to check the quality in production, and we will also need to check the bag quality after production to make sure all the bags made are in good quality.

Suggestion on QC:

You can either send somebody you know to factory to do quality check.

Or you can ask the factory to send quality check video and report.

6) Shipping + shipping terms

We will ship the bag from China to the destination. It can be shipped by express, air or sea depends on the order quantity and urgency.

Normally shipping terms as follows:

EXW

FOB

CIF

DDU

DDP

Detail Incoterms explanation from Paperindex Academy

7) Payment Terms

For all import-export business, we will need to make sure all the parties will reach the agreement in payment terms.

Normally for the flexible packaging trade, there will be:

Deposit + balance before shipment

Deposit + balance against bill of lading

For big orders with long term business relationship, there might be terms, such as net 30, net 45 days.

8) Delivery cost calculation

Cost is important for the buyer to make the decision whether to buy from China or not.

Delivery cost included all below:

Printing plate (if any)

Total order bag value amount

Shipping (sea and destination local shipping)

Tariff

Destination port local charge.

9) Lead time

Printing plate making time + production lead time + shipping from China to destination

Normally the total lead time from order placing to delivery will be around 60 days. (Depends on the sea shipping time)

10) Buying Suggestion: (According to our experience)

If you can accept the lead time, and your order quantity can reach 1 pallet, it will be cost saving to buy from China.

Conclusion:

Buying flexible packaging from China is not complicated at all, the most important point is to select the reliable supplier. You can contact us for more details if you have further questions: info@longdapac.com

This article is written by Longda Pac (www.longdapac.com), a leading flexible packaging manufacturer from China.

Please contact Longdapac for a free quote on your flexible packaging needs. We have quick response, efficient communication, quality products, on time delivery, and competitive price.

Longdapac

- Address: Plastic Packaging Base Xiong County Baoding City Hebei Province China

- Tax number: 130638601219032

- Bank: Xiong County Branch of China Construction Bank

- Bank account: 1300 1668 4080 5000 7204

- Phone: 0086-138 2882 1440

- WhatsAPP: 0086 138 2882 1440

- Fax: 86-312-5863390

- Email: info@longdapac.com