Global Mono Material Pouch market News 2023

What is Mono Material Pouch?

Mono Material Pouch is the pouch made by mono-material; which also means it is made by single type of material. Normally it is mono-material PP pouch and mono-material PE pouch, these 2 types of pouches are the most often see mono material pouch nowadays.

The biggest advantage of mono material pouch is 100% fully recyclable, without the difficulty of splitting or separating various materials.

According to the analysis of the market data forecast, the European flexible packaging market will be valued at US $28.22 billion in 2021 and will grow to US $41 billion by the end of 2026, with a CAGR of 7.76%. In addition, CE FLEX statistics show that more than 40% of food in Europe uses flexible packaging, accounting for 10% of all consumer packaging materials.

Flexible packaging is the main force of packaging industry. Compared with traditional packaging, a mono material does not need to peel off different plastics during recycling, greatly reducing the complexity of the process and facilitating recycling. At the same time, it can still guarantee the necessary functions such as packaging barrier and printability. According to the recycling nature of a mono material, it is expected to reach 100% recovery rate, which can be called a “sharp weapon” to promote the sustainable development of the packaging industry. At the same time, the market value of mono materials is also expanding. Now, mono materials have become the undisputed “tuyere” of the industry.

In this article, we will list some of the mono material pouch markets news 2023 globally.

Navigation, click to jump to the section you want to read

Global Mono Material Pouch market News 2023

1) Brookfarm Toasted Muesli

Brookfarm toasted muesli’s recyclable, high barrier stand up pouches – provide a creative approach to sustainable flexible packaging and design.

The winning package called roll ‘n’ recycle is a 100% polyethylene (PE) bag that consumers roll up after using the product. A specially designed sticker attached to the bag is used to fix the rolled up package.

The language on the sticker lets consumers know that they can roll the bag into the home recycling bin. In addition to being recyclable, the bag also has the property of protecting the cereal from deterioration. Rolling the bag into a semi-rigid 3D shape enables it to move in the existing recycling process without polluting the paper flow like other soft plastics and without affecting the rotating mechanical parts within the material recycling facility.

2) AmPrima 100% recyclable mono material pouch

This AmPrima recyclable packaging bag replaces the previous complex packaging system consisting of a tray, a cover and an outer box, and adopts a mono material and portable high barrier packaging form. After consumption, consumers can put it directly into the delivery point designated by the store or the nearest recycling bucket for recycling.

AmPrima recyclable packaging bags not only meet the growing demand of consumers for recyclable packaging, but also meet the goal of Tyson to add more sustainable materials to its brand packaging. Using the AmPrima recyclable packaging bag, the packaging weight of Tyson instant food is reduced by 75%, and the overall carbon footprint is reduced by 80%. In addition, the production water consumption of this package has also been reduced by 84%, and the chlorine based PVC material has been completely eliminated.

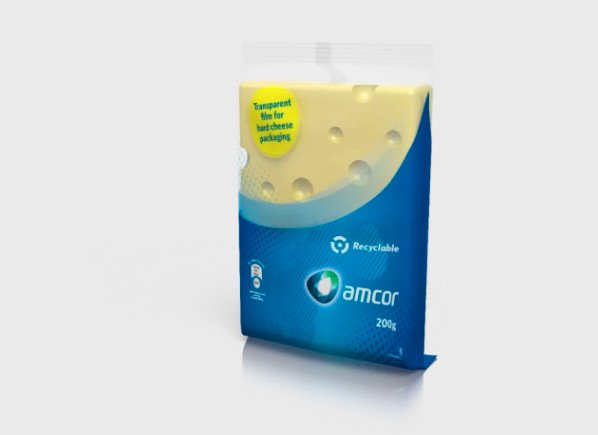

3) Mono-material PE back sealing bag solution developed by Amcor

Amcor’s mono-material PE back sealed bag solution is not only recyclable, but also maintains the long shelf life, functionality and high safety standards required for hard cheese products. Compared with the traditional OPA / PE packaging, Amcor’s new mono-material PE structure packaging reduces the use of non renewable energy by 25%, the carbon footprint by 41%, and the water consumption by 11% (calculated using Amcor’s full life cycle assessment tool asset and certified by Carbon Trust)

4) Pantene 100% recyclable mono material PE stand up spout pouch

Pantene 100% recyclable mono material PE stand up spout pouch, described by zacros as “the first mono material filled bag in Japanese history”, is laminated with a PE / PE adhesive, which provides a barrier but does not interfere with the PE recovery flow. Of course, the idea here is to let consumers pour the contents into reusable hard containers and then discard the bags in the PE recycling stream.

The challenge faced by zacros in developing this mono material bag is to select the appropriate materials, using only adhesives, inks and barrier materials less than 5% by weight, which still provide durability for liquids.

5) Mondi: replace aluminum foil with innovative high barrier mono material film

Mondi, the world’s leading packaging manufacturer, launched the retortpouch recyclable mono material cooking package, which is applied to a range of food and wet pet food. Mondi has developed an innovative high barrier film to replace aluminum foil, which can maintain high temperature during distillation and achieve shorter processing time. The new single material cooking package is completely recyclable, providing a special shelf life for the single material packaging solution and reducing potential food waste.

In early 2021, Mondi created three sustainable packaging for the new vegetarian product line of food manufacturer Orkla. It is mainly used in the flavoring products of corn cake, corn potato chip and corn roll of Orkla company.

- tortilla is Mondi’s first food packaging adopting its “barrier pack recyclable” solution. The packaging adopts a single material, which has high barrier property and light weight. The sealed tape can keep the freshness of food and extend the shelf life.

- in order to maintain the crispness and freshness of corn and potato chips, Mondi uses metal free high resistance laminate, which makes the new packaging solution completely recyclable. This package also avoids grease leakage inside.

6) BOBST: AlOx barrier layer and solvent-free adhesive solution

Swiss packaging equipment and service provider Bobst launched its “generation 2.0” high barrier flexible packaging solution in the second half of 2021, aiming to replace the multi-material packaging structure with a mono material structure, while meeting the requirements of multiple applications in terms of processability, barrier property and optical performance.

“Generation 2.0” includes new ultra-high and high barrier all polypropylene laminated bags, which can use transparent AlOx (aluminum oxide) barrier layer, and solvent-free barrier adhesive / finish. All polypropylene laminated bags can also be printed by UV flexographic printing with digital ink jet printing.

In addition, “generation 2.0” also includes all low density polyethylene laminated bags and mdo-pe laminated bags. Mdo-pe laminated bag can use high barrier solvent-free adhesive to achieve excellent barrier performance.

7) EMSUR: Single PE and PP structures adapt to multiple product types

EMSUR, a flexible packaging group, launched EM full Rflex series packaging, which is based on PE and PP single material substrates, thus replacing the traditional multi structure, providing excellent barrier and sealing performance for packaging.

The new laminated bags are targeted at a variety of FMCG categories, including snacks, sweets, coffee and tea, fresh and processed food, and home and personal care, with the aim of improving recyclability and food preservation performance.

In addition, the flexible packaging series will provide transparent and printed films with different bright and matte effects, which are suitable for intaglio and flexographic printing.

What Longdapac can help?

Longdapac is the leading flexible packaging manufacturer from China. We focus on sustainability packaging as you can see below:

Longdapac is the first high barrier MDO-PE film supplier in China.

Longdapac is the first Chinese factory who can make high barrier mono-material PE pouch.

Longdapac recyclable high barrier mono-material PE pouches can meet the recyclability of

- REDcycle in Australia

- CE FLEX in EU

- How2Recycle in USA

- SOFT PLASTIC in New Zealand

Longdapac is a BRC and ISO certified factory with annual capacity of more than 25,000 tons.

Basically Longdapac can satisfy all your recyclable packaging needs, both standard and high barrie

With our professional packaging team on artwork design, bag production, and recyclable material development, we are the first high barrier mono-material pouch manufacturer in China who can make

Recyclable Coffee Bag

Recyclable Tea Bag

Recyclable Dog Food Bag

Recyclable Cat Food Bag

Recyaclable Laminating Pouches