Mono material PE pouch & PP Pouch Trend in 2023

What is Mono Material Pouch?

Mono Material Pouch is the pouch made by mono-material; which also means it is made by single type of material. Normally it is mono-material PP pouch and mono-material PE pouch, these 2 types of pouches are the most often see mono material pouch nowadays.

The biggest advantage of mono material pouch is 100% fully recyclable, without the difficulty of splitting or separating various materials.

According to Smithers, a market research expert, the mono material plastic packaging film market may reach US $70.9 billion in 2025, with a total consumption of 26.03 million tons

Compared with traditional packaging, when a single material is recycled, it does not need to peel off different plastics, greatly reducing the complexity of the process, so it is very conducive to recycling. At the same time, it can still guarantee the necessary functions such as packaging barrier and printability.

According to the recycling nature of a single material, it is expected to reach 100% recovery rate, which can be called a “sharp weapon” to promote the sustainable development of the packaging industry. PE (polyethylene) / PP (polypropylene) and other single plastics have gradually become the “new favorite” of brands. They are not only applied to food and daily care soft packaging, but also have functional and recyclable innovations in hard packaging bottle caps.

Today we will list some of the mono material PE pouch & PP pouch global trend in 2023.

Navigation, click to jump to the section you want to read

Mono material PE pouch & PP Pouch Trend in 2023

1) L’OREAL 100% Recyclable Mono PE Spout pouch shampoo refill.

L’Oreal’s Elvive brand has cooperated with Arcade Beauty, a well-known multinational cosmetics and care packaging manufacturer, to develop a new shampoo supplement.

It is reported that the material of this flexible pouch is completely made of PE. Compared with the 250ml ordinary shampoo bottle, it reduces the material by at least 75%, and can be recycled in the PE recycling system. Arcade Beauty chooses to use PP or PE mono material to make this soft plastic pouch, which is also equipped with a lid.

Arcade Beauty launched a variety of different mono material packaging, aiming to meet the goal of many brands around the world to achieve 100% recyclable packaging or improve the recycling content of packaging.

2) Dow: high barrier mono material PE food bag

Dow has launched an innovative high barrier mono material PE food bag, which can not only realize the recycling of polyethylene, but also can not be underestimated in terms of functionality. It can be comparable to the functionality of various materials.

For example, it has certain high oxygen and water vapor barrier, printability, toughness, hardness, gloss and transparency, but it will not affect the recyclability of packaging materials.

PE high barrier stand up spout pouch with toughness, rigidity and shelf appeal.

This packaging is made of high-performance biaxially stretched polyethylene (TF-BOPE) material film and the reinforced barrier laminated film produced by Dow in the Spanish innovation center.

3) Heinz: Mono material PP baby stand up spout pouch

Heinz plans to launch a mono material baby food PP stand up spout pouch.

It is said that Heinz, in cooperation with Tesco’s technical team and the charity RECOP, is expected to make 2.8 million Heinz baby fruit stand up spout pouches “easy to recycle” and save nearly 20 tons of Heinz soft bag plastic every year.

Launched in the UK, this product is completely made of PP. Heinz describes it as “the first truly recyclable baby food stand up spout pouch”. After the evaluation of the recycling label (OPRL) on the package, it meets the requirements of “recycling”, and each package has an OPRL label.

4) High barrier mono material PP laminated pouch

According to the relevant plastic application regulations in Europe, even high barrier flexible packaging needs to be 100% recyclable by 2025. This is a big challenge for flexible packaging.

Elif is addressing this challenge through a mono material PP structure solution.

The solution aims to extend the shortest shelf life of the contents as much as possible, and protect the high aroma of the contents through a high barrier layer.

Among them, the high water vapor barrier of 0.5g/m/24h, the oxygen barrier of 0.1 cc / M / 24h and the light barrier are realized through the metallized polypropylene film, which does not need to use EVOH or PVDC barrier layer. Independent testing confirmed that the packaging has good recyclability.

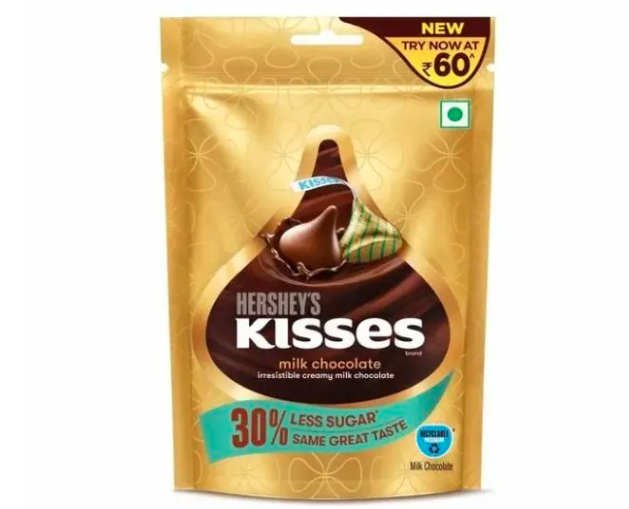

5) Hershey’s Kisses Milk Chocolate's mono material PE pouch

The sustainable packaging solution independently developed by Constantia Flexibles, one of the largest flexible packaging enterprises in Europe, recently won the 2021 Dow Packaging Innovation Award.

Constantia Flexibles and Hershey India jointly launched recyclable mono material packaging for Hershey’s Kisses milk chocolate, the latest product of Hershey India.

Constantia Flexibles provides a more sustainable barrier packaging solution for this milk chocolate packaging. This is a mono material polyethylene (PE) laminate solution, designed to be fully recyclable in the PE recycling system, while meeting all the functional and aesthetic requirements of the product. In addition, the packaging will not change the current production process and will not adversely affect the product integrity / shelf life industry. Moreover, the packaging structure and shape are maintained throughout the supply chain by enhancing the tear resistance.

What Longdapac can help?

Longdapac is the leading flexible packaging manufacturer from China. We focus on sustainability packaging as you can see below:

Longdapac is the first high barrier MDO-PE film supplier in China.

Longdapac is the first Chinese factory who can make high barrier mono-material PE pouch.

Longdapac recyclable high barrier mono-material PE pouches can meet the recyclability of

- REDcycle in Australia

- CE FLEX in EU

- How2Recycle in USA

- SOFT PLASTIC in New Zealand

Longdapac is a BRC and ISO certified factory with annual capacity of more than 25,000 tons.

Basically Longdapac can satisfy all your recyclable packaging needs, both standard and high barrie

With our professional packaging team on artwork design, bag production, and recyclable material development, we are the first high barrier mono-material pouch manufacturer in China who can make

Recyclable Coffee Bag

Recyclable Tea Bag

Recyclable Dog Food Bag

Recyclable Cat Food Bag

Recyaclable Laminating Pouches