Recyclable Flexible Packaging Development Trend in 2023

With the development of economy and the growth of population, the demand for flexible packaging is increasingly rapidly. This is causing too much plastic pollution. Sustainability is the hot topic nowadays. That’s recyclable flexible packaging is becoming development trend now.

Today we will talk about recyclable flexible packaging development trend in 2023 in details.

It’s an in-depth article that takes 20 minutes to read.

Navigation, click to jump to the section you want to read

Recyclable Flexible Packaging Development Trend in 2023

1) Flexible packaging trends

1. Resist the pressure of disposable Plastics:

It is expected that the participants in the packaging value chain and the public will promote the reduction of disposable plastic waste. Before the outbreak of COVID-19, some retailers (especially in Europe) experienced an early choice of plastic. Once the crisis is over, people may pay more attention to packaging safety as consumers’ emotions change to health and protection first. This may change consumers’ perception of packaging, making it more hygienic than sustainable.

2. E-commerce and convenience:

The rise of e-commerce and the increasing demand for convenience are shaping the expectations of new B2B and B2C customers. E-commerce and door-to-door delivery business experienced a great boost during the epidemic, but packaging needs better impact resistance and puncture resistance, because compared with the traditional value chain, they are physically processed by more people.

For example, due to sharp objects, careless handling or improper selection of packaging materials, resulting in seal failure and puncturing, leakage of fresh meat packaging is the most common complaint encountered in fresh delivery. The packaging of liquid products has also changed from rigid packaging to flexible packaging, because e-commerce purchase needs to enhance integrity.

3. Intelligent value chain:

Industry 4.0 and the Internet of things (IOT) are changing industrial production and creating new opportunities in the PE value chain. Industry 4.0 helps to ensure traceability from packaging production to final product placement on retail shelves.

This is expected to play an increasingly important role in ensuring that packaging ingredients can be tracked, especially when recycled ingredients are included.

2) Sustainability

1. Recycling design

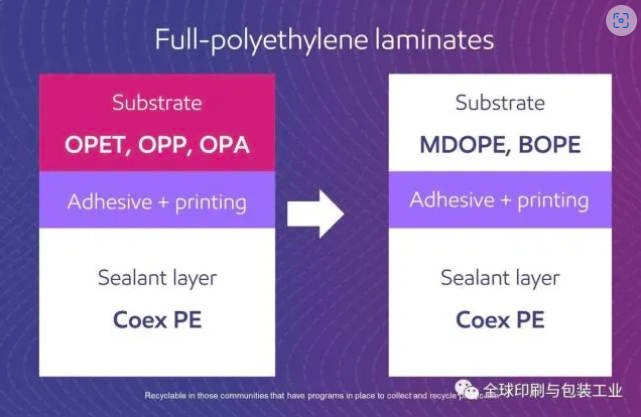

Many packaging structures traditionally use composite structures, which usually include PE films used as sealing layers, and oriented films such as polyester or PA films used as substrates. These multi-material structures are difficult to recover in the mechanical recovery process.

In recent years, people have created solutions to replace these substrates with more easily recycled PE films, and many new solutions are being developed. Special attention is paid to directional PE, whether it is MDO-PE or BOPE. These PE / PE composite films can improve recyclability and may contribute to circular economy.

2. MDO tensile resistance

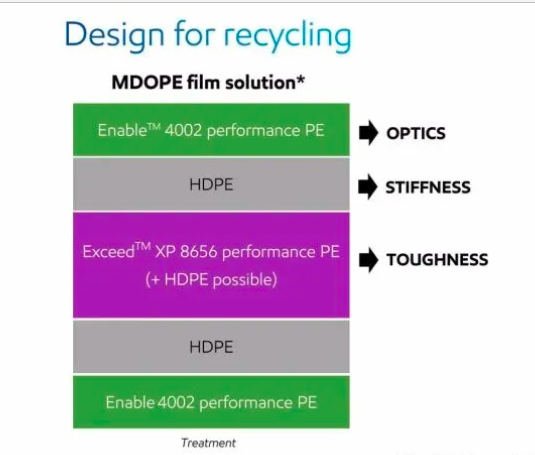

MDO process significantly improves the tensile strength in the machine direction and makes the PE film more solid during printing and lamination, which is the key to the success of sup. Since many packaging machines today are designed to handle high heat-resistant composite materials, a large amount of high-density PE (HDPE) must be added to the formulation to avoid or minimize thermal deformation during sealing.

To ensure excellent optical performance after MDO, medium density enable 4002 and enable 4009 (0.940 density) high-performance polyethylene were placed in each surface layer. Compared with other solutions, such as those using HDPE in the surface layer, they also give excellent film optical properties with lower stretching ratio. Very good optical properties can still be obtained by only 4.6 times of stretching, while HDPE resin usually needs about 6 times. The processor can stretch the film less, thereby minimizing the risk of splitting that is not conducive to production efficiency.

In order to enhance the mechanical properties and bagging performance, excellent XP high-performance polyethylene was added to the core layer. If higher heat resistance is required, some HDPE can also be added to the core layer. The MDO film compounded on the PE sealing film has similar bag dropping performance as OPA / PE composite. As for further development, ExxonMobil is currently studying the solution of integrating gas barrier into mdope / PE Composites while maintaining performance and recycling opportunities.

3. Remove PA

The multi-layer coextrusion structure containing PA may be an important problem for recycling. These structures are commonly used in thermoforming applications and contain 30% – 50% PA. PA has a wide range of applications, with characteristics such as adhesion, puncture resistance, wear resistance, easy to heat forming and barrier.

Removing PA from these multilayer structures is a key goal to improve recyclability. Excellent XP 6026 and 6056 high performance polyethylene can be used to improve puncture resistance and reduce the thickness of PA layer. PA can be reduced by 30% while enhancing puncture resistance. Development work is currently under way to further reduce or remove PA in these multilayer films, which can be easily recycled just as the development work on PE thermoformed films or at least polyolefin thermoformed films.

4. Upgrading recycled steams

In the foreseeable future, difficult to recycle mixed polymer streams will continue to be a challenge for the industry. Compatibilizers that can combine polyolefins with incompatible polymers while minimizing performance loss are being developed.

If there is no compatibilizer, PA can not be well dispersed into the PE substrate, thus reducing the performance of PE. The addition of effective compatibilizers helps to disperse PA into smaller inclusions and combine it with PE.

The influence of compatibilizers on the performance may be enormous. This chart highlights the performance of compatibilizers based on MAH grafted vistamaxx high performance polymers in industrial post circulation streams containing PE, polypropylene (PP), PA and EVOH. The structure represented by the gray shaded area is made of 100% recycled ingredients and has poor performance. Adding compatibilizers can significantly improve mechanical properties, such as dart resistance, tear resistance and puncture resistance

5. Increasing recycled content

One problem associated with adding recycled ingredients to the formulation is that it adversely affects the performance of the final product. Adding high-performance polymers such as exceed XP can improve performance.

Thin film structure made of 70% LLDPE and 30% LDPE. The introduction of 75% excellent XP 8656 high-performance polyethylene in the surface layer allows up to 100% recycled resin to be used in the core layer, while the film characteristics suitable for the application are similar to that of the reference film, which is made of the original polymer and can be maintained.

Another way to consider the impact of high-performance PE polymers on the entire film is to use 38% excess XP to allow the introduction of up to 50% recycled material. Using a similar concept, the cooperation between the Barbier group, a leading French PE film processor and recycler, and ExxonMobil has led to the production of finishing shrink films containing 50% post consumer recycled components and enable 4002 high-performance polymers as performance boosters. Packaging with minimal risk of damage does not reduce mechanical properties, while optical properties (such as gloss and transparency) enable brand owners to effectively promote products.

What Longdapac can help?

Longdapac is the leading flexible packaging manufacturer from China. We focus on sustainability packaging as you can see below:

Longdapac is the first high barrier MDO-PE film supplier in China.

Longdapac is the first Chinese factory who can make high barrier mono-material PE pouch.

Longdapac recyclable high barrier mono-material PE pouches can meet the recyclability of

- REDcycle in Australia

- CE FLEX in EU

- How2Recycle in USA

- SOFT PLASTIC in New Zealand

Longdapac is a BRC and ISO certified factory with annual capacity of more than 25,000 tons.

Basically Longdapac can satisfy all your recyclable packaging needs, both standard and high barrie

With our professional packaging team on artwork design, bag production, and recyclable material development, we are the first high barrier mono-material pouch manufacturer in China who can make

Recyclable Coffee Bag

Recyclable Tea Bag

Recyclable Dog Food Bag

Recyclable Cat Food Bag

Recyaclable Laminating Pouches